Читайте также:

|

• Visually inspect the shock absorber(s) and check that there is no sign of oil leakage from its damper. This is somewhat restricted on certain single shock models due to the location of the shock absorber.

• With the rear wheel raised off the ground, grasp the wheel at the highest point

Brakes, Wheels and

and attempt to pull It up (see illustration 8). Any play in the swingarm pivot or suspension linkage bearings will be felt as movement. Note: Do not confuse play with actual suspension movement. Failure to lubricate suspension linkage bearings can lead to bearing failure (see illustration 9).

Tyres

• With the rear wheel raised off the ground, grasp the swingarm ends and attempt to move the swingarm from side to side and forwards and backwards - any play indicates wear of the swingarm pivot bearings (see illustration 10).

Brakes

• With the wheel raised off the ground, apply the brake then free it off, and check that the wheel is about to revolve freely without brake drag.

• On disc brakes, examine the disc itself. Check that it is securely mounted and not cracked.

• On disc brakes, view the pod material through the caliper mouth and check that the pads are not worn down beyond the limit (see illustration 11).

• On drum brakes, check that when the brake is applied the angle between the operating lever and cable or rod is not too great (see illustration 12). Check also that the operating lever doesn't foul any other components.

• On disc brakes, examine the flexible hoses from top to bottom. Have an assistant hold the brake on so that the fluid in the hose is under pressure, and check that there is no sign of fluid leakage, bulges or cracking. If there are any metal brake pipes or unions, check that these are free from corrosion and damage. Where a brake-linked anti-dive system is fitted, check the hoses to the anti-dive in a similar manner.

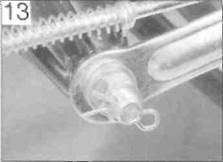

• Check that the rear brake torque arm is secure and that Its fasteners are secured by self-locking nuts or castellated nuts with split-pins or R-pins (see illustration 13).

• On models with ABS, check that the self-check warning light in the instrument panel works.

• The MOT tester will perform a test of the motorcycle's braking efficiency based on a calculation of rider and motorcycle weight. Although this cannot be carried out at home, you can at least ensure that the braking

systems are properly maintained. For hydraulic disc brakes, check the fluid level. lever/pedal feel (bleed of air if its spongy) and pad material. For drum brakes, check adjustment, cable or rod operation and shoe lining thickness.

Wheels and tyres

• Check the wheel condition. Cast wheels should be free from cracks and if of the built-up design, all fasteners should be secure. Spoked wheels should be checked for broken, corroded, loose or bent spokes.

• With the wheel raised off the ground, spin the wheel and visually check that the tyre and wheel run true. Check that the tyre does not foul the suspension or mudguards.

|

| щ | |||

| I | i | ||

| I | |||

| Brake pad wear can usually be viewed without removing the caliper. Most pads |

Дата добавления: 2015-10-29; просмотров: 137 | Нарушение авторских прав

| <== предыдущая страница | | | следующая страница ==> |

| Front wheel mounted on a surface plate for steering head bearing lower race check | | | Tyre direction of rotation arrow can be found on tyre sidewall |