Читайте также:

|

• Ball and roller bearings will fail due to lack of lubrication or damage to the balls or rollers. Tapered-roller bearings can be damaged by overloading them. Unless the bearing is sealed on both sides, wash it in paraffin (kerosene) to remove all old grease then allow it to dry. Make a visual inspection looking to dented balls or rollers, damaged cages and worn or pitted races (see illustration 5.18).

• A ball bearing can be checked for wear by listening to it when spun. Apply a film of light oil to the bearing and hold it close to the ear - hold the outer race with one hand and spin the inner

Hold outer race and listen to inner race when spun

race with the other hand (see illustration 5.19). The bearing should be almost silent when spun; if it grates or rattles it is worn.

6 Oil seals

Oil seal removal and installation

|

• Oil seals should be renewed every time a component is dismantled. This is because the seal lips will become set to the sealing surface and will not necessarily reseal.

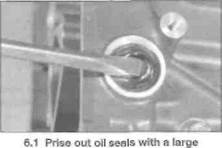

• Oil seals can be prised out of position using a large flat-bladed screwdriver (see illustration 6.1). In the case of crankcase seals, check first that the seal is not lipped on the inside, preventing its removal with the crankcases joined.

Flat-bladed screwdriver

• New seals are usjally installed with their marked face (containing the seal reference code) outwards and the spring side towards the fluid being retained. In certain cases, such as a two-stroke engine crankshaft seal, a double lipped seal may be used due to there being fluid or gas on each side of the joint.

Tools and Workshop Tips REF»17

• Use a bearing driver or socket which

bears only on the outer hard edge of the seal

to install it in the casing - tapping on the inner

edge will damage the sealing lip.

Oil seal types and markings

• Oil seals are usually of the single-lipped type. Double-lipped seals are found where a liquid or gas is on both sides of the joint.

• Oil seals can harden and lose their sealing ability if the motorcycle has been in storage for a long period - renewal is the only solution.

• Oil seal manufacturers also conform to the ISO markings for seal size - these are moulded into the outer face of the seal (see illustration 6.2).

These oil seal markings indicate

Inside diameter, outside diameter

Дата добавления: 2015-10-29; просмотров: 147 | Нарушение авторских прав

| <== предыдущая страница | | | следующая страница ==> |

| Temperature change | | | Breaking and joining final drive chains |