Читайте также:

|

Front suspension travel: 200 mm

Rear suspension travel: 55 mm

Weight

Mass: 38 kg (without driver), 118kg (with driver)

Weight: 441 N; 48% on the front axle, 52% on the rear axle

Centre of the gravity without driver apportioned approximately in equal parts to the front and rear axle. But if there is a driver on the bike, force on the rear axle is higher than at the front. For distribution of the force equally between front and rear axles, we placed in front of the user a battery and a box for pizza.

Chassis frame

Exploring a lot of frame structures and materials, we chose duplex titanium frame structure.

The main advantages of the duplex titanium frame structure are lightness, simplicity and ruggedness. By using tubes with the bigger diameter on 10 mm than steel tubes we reached the goal to make our frame rigid as a steel frame (because strength limit of titanium is less than it has steel). The larger diameter - the larger contact area among tubes in a welding place, means the larger ruggedness of the frame structure. But titanium tubes are lighter on 43% than steel tubes. Consequently, by using titanium tubes we made rigid and light frame. Let’s watch the simulation frame video about axial stress and bend.

| Minimum coefficient of the strength margin=1.9 |

| Static analysis |

Rear suspension

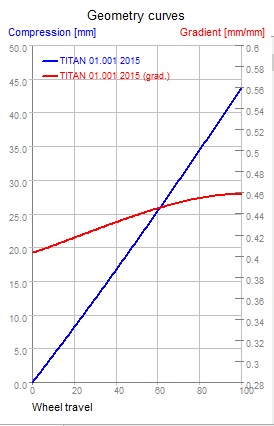

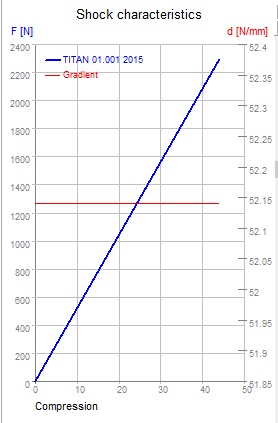

For analyzing rear suspension geometry we use Linkage Personal Version software. Also we explored the rear suspension geometry of MIG-1 and MIG-2 and we decided that applying of only one pendulum and rear spring are not enough for stiffness of the frame structure.

If we will make more difficult structure of the pendulum, bike’s weight will rather increase. That’s why we decided to use rear single hinge suspension. It consists of the pendulum, the cross slide extension, the rocker actuator and the spring. This kind of suspension is more effective for moving on the road through the obstacles. The pendulum is made of steel sheets, which depth is 2 mm, bended for achieving needed shape. The torque from the pendulum is transmitted to cross slide extension and then it goes to rocker actuator through the hinged connections. Thanks to the device as cross slide extension we can use lighter spring, which will has an equal spring stiffness as a hard and strong spring. The rocker actuator has leverage 1:1. It is made from aluminum. It changes line of action force for ride quality. Finally, changed torque turns into the compressibility of the rear spring. In such way, bike’s rear suspension is not heavy, and it is effective for city roads because of the ride performance.

Front suspension

In front suspension we use Marzocchi 888 RC3 EVO V2'14 fork. RC3 EVO has an adjustable rebound, high speed compression, volume and stiffness. The fork has an adjustable compression rate, which allows you to configurate the plug so it`s in all conditions the wheel will have constant contact with the ground, leaping backward over rocks and roots, and consequently will improve the handling of the bike and your safety. An adjustable high speed compression (is automatically adjusted during adjustment of the speed of compression) is triggered during a sharp impact and triggered on the last 3-4 cm of stroke, preventing a hard blow, and as a consequence loss of control.

Wheels and tires

Exploring MIG-1 and MIG-2, we discovered one problem which name is wobbling. We decided to change bicycle’s rim to motorcycle’s for increasing stiffness on the obstacles. Also we changed type of the wheel structure that is method of controlling wobbling. We use 16” front and rear wheels because they are light. Bike with these wheels is more dynamic, because center of gravity a bit decreased. Thank to this, readability of our bike increased, cornering ability became a little bit better that is important fact for riding on the city’s roads.

| Center of Gravity |

Brake system

As for competitions and for city riding there are a lot of obstacles. For undergoing this test successfully, bike must have qualitative brake system. When we were choosing brakes for our bike, we analyzed benefits and limitations of different brakes. For city riding there is need to increase braking power on the front brakes, to improve their stiffness and to reduce general unsprung mass, because smaller stopping time provides bigger speed before the corner, as a result faster lap time, lower force on brake lever leads to better control by driver of braking process, lower unsprung mass improves suspension qualities.

Because of high deceleration and weight distribution to prevent lack of brake power on the front wheel several decisions have been made. New front Hope-TECH 3 V4 brakes were installed, these 4 piston calipers have sufficient piston and pad area to cope with increased braking power.

This system has front floating vented brake discs with 203 mm diameter. Vented brake disc helps to reduce temperature of the braking surface by 15%. It is very important when you ride on the steep descents or other places where you might face with slumping of the power due to overheating.

Caliper V4 is made of solid aluminum. This structure gives increased rigidity for better braking. Increased square of the braking pads improves heat out and extends the life of the brakes.

For rear wheel we chose Shimano Deore BL-M615 brakes with floating 203 mm brake discs.

| The Conservation of Energy | |||

| Mass bike(kg)= | |||

| Mass pilot (kg)= | |||

| v (m/s)= | 22,22 | ||

| Kinetic energy (Dj)= | 30858,025 | ||

| Kinetic energy is converted into thermal energy | |||

| Mass front brake disc (kg)= | 0,283 | ||

| Mass rear brake disc (kg)= | 0,405 | ||

| Specific heat rotor (Dj/kg*°C)= | |||

| Temperature rise (°C)= | |||

| Thermal energy (Dj)= | |||

| The brake lever | |||

| M (kg)= | 19,5 | ||

| L1 (mm)= | 11,35 | ||

| L2 (mm)= | 49,25 | ||

| Force input (N)= | 191,1 | ||

| Force output (N)= | 829,222467 | ||

| The master cylinder | |||

| Full stroke (mm)= | 10,5 | ||

| Piston diameter front (mm)= | Piston diameter rear (mm) | ||

| Area piston (m^2)= | 0,000176709 | Area pistons (m^2)= | 0,000176709 |

| Pressure (Pa)= | 4692587,627 | Pressure (Pa)= | 4692587,627 |

| Front displacement liguid (cm^3)= | 1,575 | Rear displacement liquid (cm^3)= | 1,575 |

| The caliper | |||

| Pistone diameter front (mm)= | Piston diameter rear (mm) | ||

| Area pistons (m^2)= | 0,000226973 | Area pistons (m^2)= | 0,00031415 |

| One-side force (N)= | 1065,092451 | One-side force (N)= | 1474,176403 |

| Force caliper (N)= | 2130,184902 | Force caliper (N)= | 2948,352806 |

| The brake pads | |||

| Front | Rear | ||

| Coefficient friction = | 0,4 | Coefficient friction = | 0,4 |

| Friction force (N)= | 852,0739609 | Friction force (N)= | 1179,341122 |

| The rotor | |||

| Front | Rear | ||

| Torque tire=Torque wheel=Torque rotor | |||

| Effecctive radius (m)= | 0,09225 | Effecctive radius (m)= | 0,09225 |

| Torque rotor (Nm)= | 78,6038229 | Torque rotor (Nm)= | 108,7942185 |

| The tire | |||

| Front | Rear | ||

| Effective rolling radius (m)= | 0,2032 | Effective rolling radius (m)= | 0,2032 |

| Force tire (N)= | 386,8298371 | Force tire (N)= | 535,4046188 |

| Total braking force (N)= | 922,2344559 |

| Deceleration of vehicle in motion | |||

| Deceleration (m/s^2)= | 7,377875647 | ||

| Stopping distance | |||

| Stopping distance (m)= | 33,46006517 | ||

| Static weight distribution | |||

| Front axle verticale force (N)= | 386,3 | ||

| Percent front weight (%)= | 37,34375 | ||

| Wheelbase (m)= | 1,28 | ||

| Center of gravity front= | 0,802 | ||

| Rear axle verticale force (N)= | 648,1435146 | ||

| Percent rear weight (%)= | 62,65625 | ||

| Center of gravity rear= | 0,478 | ||

| Total vehicle vertical force (N)= | 1034,443515 | ||

| Dynamic impacts of vehicles experiencing deceleration | |||

| Vertical distance from the CG to ground (m)= | 0,827 | ||

| Weight transferred = | 503,1617007 | ||

| Front axle dynamic verticale force (N)= | 889,4617007 | ||

| Rear axle dynamic verticale force (N)= | 144,9818139 | ||

| Effects of Weight Transfer on Tire Output | |||

| Coefficient friction tires= | 0,9 | ||

| Front tire braking force (N)= | 800,5155306 | ||

| Rear tire braking force (N)= | 130,4836325 | ||

| Total tire braking force (N)= | 930,9991632 | ||

| Calculation optium brake balance | |||

| 2,072263864 | 0,201319044 | static | |

| 0,9 | 0,9 | dynamic | |

| Required front torque rotor (Nm)= | 83,8736002 | Required rear torque rotor (Nm)= | 135,8770912 |

Design and style

Every vehicle should be multipurpose. Engineers must always design their vehicle for users. Design and style begins with wheels of the e-bike. All components of the bike are exhibited comfortable for using and riding. There is innovation construction and futuristic design. Design of MIG-Titan provides place for pizza because our bike is built for pizza’s couriers. For this goal we made box which dimensions are 320х320х50 mm. Box accommodates 3 pizzas, each of them has depth 15 mm. Structure of this box is difficult but it blends with general bike’s style.

The appearance of the bike plays an important role when we are selling our product. That’s why it is important to make bike’s design not only multifunctional, it should be beautiful and it should harmonize with city style.

Дата добавления: 2015-10-23; просмотров: 120 | Нарушение авторских прав

| <== предыдущая страница | | | следующая страница ==> |

| Performance specification | | | Other mechanical components |