|

Читайте также: |

Know how to read contour peaks and valleys

Concave has hatcher marks

Know the correct and incorrect ways in which contours are drawn.

· Contours always occur in pairs

· Contours never cross (exception is an overhanging bridge, cliff or other natural feature.)

· Contours always close on themselves – complete a loop –even if miles away from a site. If a contour closes on itself on your plan it is either a high point or a low point of topography.

· Contours have both a vertical reading and a topographical reading of distance between contours

· Are always equal in vertical separation ie. Expressed in 1’, 2’, 5’, 10’ etc. once designated

· Steepest slope is a line perpendicular to the contour.

· Water always flow along the line of the steepest slope

· Existing contour lines (as the natural ground exists before change) is always drawn as a dashed line

· Proposed contour lines (one which shows how it will be altered) is always drawn with a solid line on the plan

· Alteration to ground surface is called “Grading”

· Grading is an integral part of landscape design & contour should be an important guide in the design stage – not left to fit the design.

What is the minimum width a walkway to accommodate two people side by side?

5’wide, and up to 12’long. Slope of less than 1%. 2% is ideal for water run-off.

What are the advantages and disadvantages of using asphalt?

1. Non glare, less expensive than concrete, easy to install, Color less obtrusive, expands and contracts better than concrete, No joints required, can be patterned and stamped (brick look).

2. Heats up and becomes hotter (darker material

3. Cannot withstand prolonged weight in hot weather (objects sink in it)

4. Prone to pitting with gas and other petroleum products drip on it.

5. Not as long lived (needs seal coats)

6. Alligators with age

7. Disagreeable color when new

8. Short term odor

9. Clumps if sinkhole under it

10. Lasts 15-20 years

What are the advantages and disadvantages of using concrete?

• Tremendous strength from slow curing (after30 days).

• Relatively easy to install

• Can have several choices of surfaces, colored, brushed or textured, press crete etc..

• Mixes beautifully with other surfaces, ie. brick patterns etc

• Year around usage, reflects light so it doesn’t get as hot as asphalt.

• Adaptable to curvilinear forms with steel edging etc.

• Long lasting

• Joints are required

• Some surfaces are aesthetically unappealing

• Can disintegrate if not properly prepared & poured.

• Deicing salts can damage it.

• Light color is reflective and can cause glare

• Can crack in temperature extremes

• Low resiliency – can break when things are dropped on it.

• More expensive than asphalt but less than brick or stone

• Rather common and not as decorative.

What are the reasons one might use brick or stone over a sand base rather than brick or stone over mortared concrete?

According to several paver manufacturers, paving blocks can be installed on top of concrete without mortar if you first lay down a 1/2″ to 1” bed of coarse sand. The process is nearly identical to laying a paver patio over ground.

However, this type of installation should be done with caution, since drainage, settling, and cracking can be a problem. Keep these tips in mind when laying pavers over a concrete patio:

Drainage: The biggest problem with laying pavers over a concrete slab is the inability for water to drain through the blocks and down into the earth. Before you begin, make sure your concrete is properly sloped and doesn’t puddle. Keep this drainage slope in mind when adding your pavers, and make sure the edge that drains water stays low and permeable. You can also drill small drainage holes through the concrete every few inches, to help any puddling water seep into the ground.

Sand in Joints: When you’re finished laying the blocks, firm them up by filling the joints with polymeric sand. While sand joints are still permeable, if properly set they can help excess water run off the surface rather than puddling.

Edging: Like any other type of installation, a concrete slab paver patio needs to be firmly edged, to keep the sand and pavers from settling and squishing around. However, your edging needs to allow for water to drain; if it’s watertight, your patio could turn into a bowl of water when it rains.

Red brick pavers

Semi-Mortared: Rather than dealing with edging, some builders use mortar or adhesive to hold the perimeter course of pavers in place. To do this, you’ll need a clean perimeter around the sand bed, so the blocks can stick directly to the concrete. Make sure the mortar and sand bed are the same thickness, so the blocks will be level. This method can create a nonpermeable edge that could cause water to puddle under the pavers.

Height: Your new patio will be up to 3” higher than the original concrete slab. Be sure to plan for transitions to other areas, especially if the patio adjoins your house. Most building codes specify how far a masonry patio should be from a home’s siding, and you may need to install flashing to keep water away from the house.

Concrete Condition: If the concrete slab is broken or in terrible shape, you might be better off ripping it up and starting over.

Not for Driveways: In general, this isn’t a good method for driveways. The underlying concrete doesn’t allow for the pavers to give, so they’re more likely to rock and crack.

Patio Extension: You can also extend the size of your patio, by digging out the soil around it and installing a proper gravel and sand bed, then screeding and tamping the sand across both the old and new areas to make it level. However, keep in mind that the non-concreted areas will be more likely to settle, and over time your patio may become uneven.

Don’t Rule Out Mortar: If you’re new to this project, don’t be intimidated by the prospects of mortaring a permanent paver patio. In my opinion, mortar would be less work!

What is the purpose of using an admix in concrete?

With the use of admixtures, you can have more control over your concrete. Admixtures can restore loads of concrete that might need to be rejected due to delays or other complications. They can improve the performance of problem concrete by modifying its characteristics and enhancing workability.

Admixes are used to improve the workability of the concrete by minimizing the separation coarse and fine aggregates in the mix while it’s being poured.

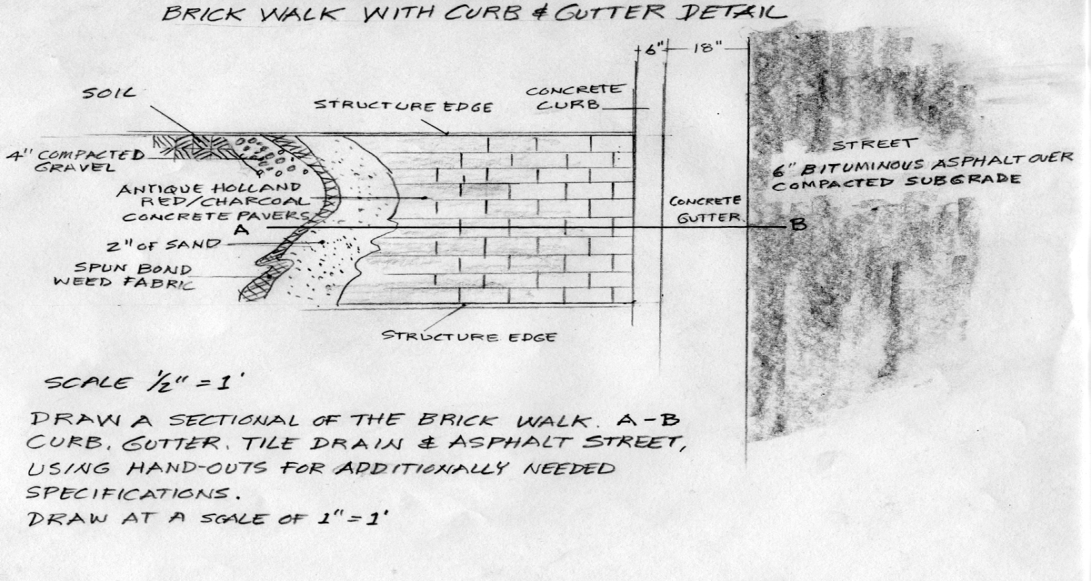

Know how to draw a cross section of a brick wall over sand

What is the recommended riser and tread dimensions for out of doors?

2x riser plus tread….2x6” + 14= 26”

What is the recommended rise in the amount of run for a handicapped ramp or walkway in Michigan?

ADA regulations require a 1:12 slope or less, which means for every inch of rise you need a foot of run, or for 21" of rise you need a 21' long ramp.

What other construction requirements are there besides the slope, for a handicapped ramp to meet handicapped laws?

For what purposes are curbs and edges used?

They separate the road from the roadside, discouraging drivers from parking or driving on sidewalks and lawns. They also provide structural support to the pavement edge. Curbs can be used to channel runoff water from rain, or melted snow and ice into storm drains. There is also an aesthetic aspect, in that curbs look formal and "finished".

Terms:

Contour Line: “A line on a plan or drawing that connects all points that are an equal vertical distance above or below a horizontal plane”

Cement is a binder, a substance that sets and hardens independently, and can bind other materials together.

Mortar is a workable paste used to bind construction blocks together and fill the gaps between them.

Polymeric sand Polymeric sand is used to fill the joints between pavers, including concrete pavers, brick pavers, and stone pavers. This product is a fine sand combined with additives, usually silica, that, when mixed with water, form a binding agent. These binders lock the sand particles together, which helps lock all the pavers together.

Concrete Slump Test- A cone mold 12” tall x 4” wide at top & 8” wide at bottom is filled with concrete mix a third at a time and rodded 25 times after each pouring. then the top is smoothed off and the cone is lifted off. Concrete should have little or no slump & not collapse.

Admix

Дата добавления: 2015-10-24; просмотров: 91 | Нарушение авторских прав

| <== предыдущая страница | | | следующая страница ==> |

| LOLLAPALOOZA TOUR JOURNAL | | | В культурной политике |