Читайте также:

|

Inspection and control.

Table of content.

| Section | Title | Page |

| 8.1 | Inspection at shoppriming | 8.2 |

| 8.2 | Inspection of steel work (Pre-blasting preparation) | 8.3 |

| 8.3 8.3.1 8.3.2 8.3.3 8.4.4 | Inspection of surface preparation Cleanliness. Solvent cleaning. SSPS-SP1 The evaluation of present condition (Rust grades and visual cleanliness. Inspection of surface preparation Cleanliness after surface preparation | 8.4 8.4 8.5 8.6 8.11 |

| 8.4 8.4.1 8.4.2 8.4.3 8.4.4 | Inspection before and during application Technical data sheet, TDS Correct mixing and thinning Wet film thickness (WFT) Climatic conditions | 8.16 8.17 8.17 8.18 8.19 |

| 8.5 8.5.1 8.5.2 8.5.3 8.5.4 | Inspection after application Dry film thickness (DFT) Curing / drying Adhesion control by pull-off test Holiday detector | 8.19 8.20 8.23 8.24 8.27 |

| 8.6 | Records of work and working conditions | 8.28 |

Inspection and control.

As mentioned in the introduction the human factor is the most critical part in achieving the specified quality for the coating system. It is therefore of major importance to carry out inspection of the work. This section of the textbook will describe what to inspect when, and the tools available for the inspector during the work. The following section “Paint failures” will describe the kind of failures one may experience and the necessary remedial actions.

During the production of a construction, inspection should be carried out at the following critical stages:

1. Inspection at shop-priming

2. Inspection of surface preparation

3. Inspection before and during application

4. Inspection after application

Each of these points is described below. Further, the inspector shall inspect / verify and document that the work is:

· In accordance with the specification

· In accordance with normal practice of good workmanship

· In line with the paint manufacturer’s requirements for the product.

If not so, proper remedial actions must be taken and the results inspected and approved before the work proceeds.

Inspection at shop priming

In recent years there has been some discussion whether the shop primer should be allowed to remain on the steel, or to be partly or completely removed prior to further painting. Any shop primer remaining necessitates an even more thorough inspection at the shop, as the shop primer will be a part of the long-term protective paint system of the structure. Inspection at shop-priming plant includes:

· Only steel with rust grade A or B (ISO 8501-1) should be used for shop priming.

· Shopprimer must be applied to a shot or grit-blasted substrate with a minimum blast cleaning quality of Sa 2 ½ (ISO 8501-1).

· Correct Dry Film Thickness, DFT of approximately 15 microns due to welding and cutting (as per manufacturer’s recommendation).

· Satisfactory curing / drying process (no damages caused by conveyer).

Inspection of steel work (Pre-blasting preparation)

When a new construction is made or when maintenance work includes steel exchange or blast cleaning the steelwork must be checked for:

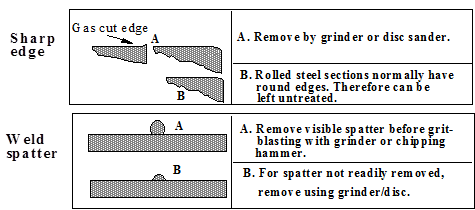

· Rounding of sharp edges.

· Smoothing of rough welding seams.

· Removal / grinding of weld spatter and beads.

· Cracks and pittings.

· Surface faults like laminations etc.

This work should be done according to the specification or ISO 12944-3 (Design considerations), and should be done in the welding shop before handling over for surface preparation and painting.

Figure 8.1.

Edges must be rounded and weld

spatter must be removed prior to the surface preparation

Figure 8.2.

Дата добавления: 2015-10-29; просмотров: 189 | Нарушение авторских прав

| <== предыдущая страница | | | следующая страница ==> |

| Создание запроса-выборки | | | Methods for solvent cleaning. |