Architecture of Samoa

From Wikipedia, the free encyclopedia

Interior fale, Apia,D'Urville, 1842

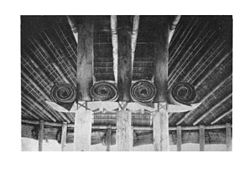

interior fale tele with central pillars and curved rafters

The architecture of Samoa is characterised by openness, with the design mirroring the culture and life of the Samoan people who inhabit the Samoa Islands.[1] Architectural concepts are incorporated into Samoan proverbs, oratory and metaphors, as well as linking to other art forms in Samoa, such as boat building and tattooing. The spaces outside and inside of traditional Samoan architecture are part of cultural form, ceremony and ritual.

Fale is the Samoan word for all types of houses, from small to large.

In general, traditional Samoan architecture is characterized by an oval or circular shape, with wooden posts holding up a domed roof. There are no walls. The base of the architecture is a skeleton frame.

Before European arrival and the availability of Western materials, a Samoan fale did not use any metal in its construction.

Contents

Lashing ʻAfa

Similar Fijian lashing (magimagi)

afa woven pattern

The fale is lashed and tied together with a plaited sennit rope called ʻafa, handmade from dried coconut fibre. The ʻafa is woven tight in complex patterns around the wooden frame, and binds the entire construction together. ʻAfa is made from the husk of certain varieties of coconuts with long fibres, particularly the niu'afa (afa palm). The husks are soaked in fresh water to soften the interfibrous portion. The husks from mature nuts must be soaked from four to five weeks, or perhaps even longer, and very mature fibre is best soaked in salt water, but the green husk from a special variety of coconut is ready in four or five days. Soaking is considered to improve the quality of the fibre. Old men or women then beat the husk with a mallet on a wooden anvil to separate the fibres, which, after a further washing to remove interfibrous material, are tied together in bundles and dried in the sun. When this stage is completed, the fibres are manufactured into sennit by plaiting, a task usually done by elderly men or matai, and performed at their leisure. This usually involves them seated on the ground rolling the dried fibre strands against their bare thigh by hand, until heavier strands are formed. These long, thin strands are then woven together into a three-ply plait, often in long lengths, that is the finished sennit. The sennit is then coiled in bundles or wound tightly in very neat cylindrical rolls.[2]

Making enough lengths of afa for an entire house can take months of work. The construction of an ordinary traditional fale is estimated to use 30,000 to 50,000 feet of ʻafa. The lashing construction of the Samoan fale is one of the great architectural achievements of Polynesia.[1] A similar lashing technique was also used in traditional boat building, where planks of wood were 'sewn' together in parts. ʻAfa has many other uses in Samoan material culture, including ceremonial items, such as the fue fly whisk, a symbol of orator status. This lashing technique was also used in other parts of Polynesia, such ase the magimagi of Fiji.

Дата добавления: 2015-10-26; просмотров: 123 | Нарушение авторских прав

| <== предыдущая страница | | | следующая страница ==> |

| Speciality: 5B072900- "Construction". for 2014 academic year. | | | Cultural Space |