Читайте также:

|

In connection with existence at our country of the Food program a considerable place in its realization the use of aviation turbo-engines (ГТД) must get in a national industry. Considerable losses of harvest at his storage is related to humidity of agrarian production. In the last years apply the artificial drying of hay, potato and grain. It is set that due to previous drainage of tubers of potato of loss of her at the protracted storage diminish in 5 - 8 times [2].The increase of scales of agricultures stipulates the considerable losses of energy and material facilities on realization of technological process of removal of surface humidity. Therefore development of highly economic and cheap power plants for drying of agrarian products has a large meaning to national economy value.

For determination of parameters of power plants which are intended for the removal of surface humidity and drying of agrarian products, it is necessary to know parameters which characterize a process of humidity removal. This process is difficult and determined by the processes of heat mass transfer of humidity. Thus the process of humidity removal is different for evaporation of humidity from inner and outer surface of product.

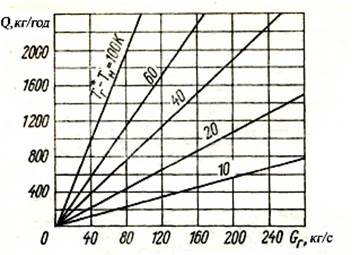

For evaluation calculations which are executed on the stage of basic parameters of drying options grounding, it is possible to take advantage of the well-known thesis of theory of mass transfer in accordance with which in a period with permanent (permanent) speed of drainage in a middle porous damp material of transference of damp to the surface place is taken at a liquid phase. In accordance to this for determination of basic parameters of drying options from GTE it is possible to use experimental data about speed of humidity removal at the convective action of gas stream, fig.1.

Fig.1. Dependence of humidity removal speed from the potato surface with gas consumption

and it’s temperature

On this picture dependence of speed of separation of surface humidity from the bubbles of potato from the second mass consumption of gas and it's temperature at average speed of air at the clamp of potato of V=of 10м/с is shown.

For every type of agrarian product there is a limit of temperature of heat carrier, higher of which there can be irreversible biological changes in a product. For example, for a potato extreme temperature is equal to 50 оС. At known temperature of heat carrier and productivity of humidity the removal of Q can be defined necessary amount of heat transfer of Gg.

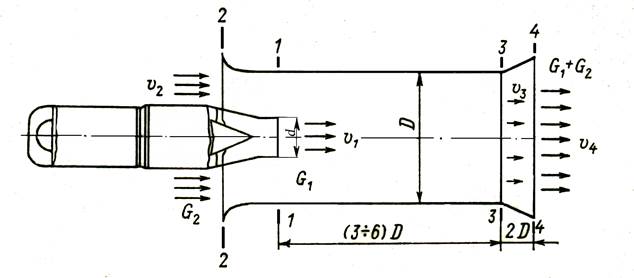

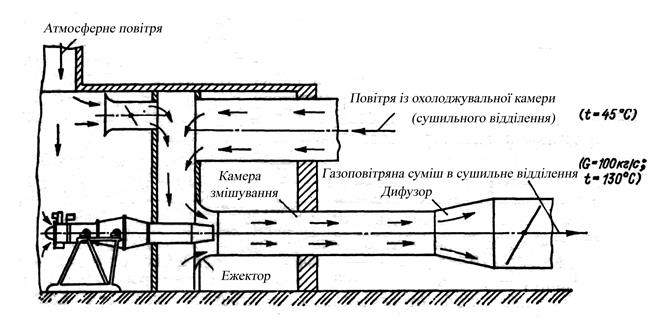

Usually for drainage of agrarian product the small temperature of heat transfer is needed. At the low temperature surface drying effective enough is application of GTE together with ejector (pic.2)

Pic.2. Ejector waste gas generator with GTE application

Main parameters of ejector waste gas generator are relative air loss, relative cross section area of ejector and ejector expansion degree.

Relative air loss n is air consumption G2, which is get to ejector enter to gas consumption G2 through the GTE nozzle ratio, i.e.  .

.

Relative cross sectional area of ejector β is the ratio of ejector surface F1 ( without GTE nozzle area) to the outlet cross sectional area of nozzle F1c, i.e.  .

.

Degree of ejector expansion f is the ratio of the outlet cross sectional area of ejector diffuser F4 to it’s inlet cross sectional area F3, i.e.  .

.

In turn relative air loss n is related with other relative parameters of ejector by next dependence:

, (1)

, (1)

where γ-relative density of working body, i.e.  .

.

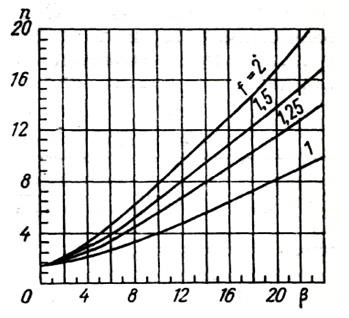

At pic. 3 there is graphical interpretation of dependence (1) at γ = 1. If there are known relative parameters of ejector, can be defined parameters of working body (gas) at it’s inlet - Т 3, υ 3, υ 4,  , i.e.

, i.e.

temperature of gas  , (2)

, (2)

where Тн – atmospheric air temperature;

speed of air stream at diffuser inlet  ;

;

speed of air stream at diffuser outlet  ;

;

total pressure of gas stream at diffuser outlet  .

.

Pic.3. Dependence of relative air consumption n on relative ejector area β

and degree of ejector expansion f

At pic. 4 there is scheme of ejector power plant for grain drying on Omsk elevator. Power plant has productivity П=100 t/hour and consist of heat generator (aviation GTE) of type Д-25ТГ, fundamental frame, ejector, mixing chamber, diffuser and air-gas pipelines with bolts which are regulated.

Pic.4. Scheme of ejector power plant for grain drying

This plant is successfully exploited on the Omsk elevator from 1964 years with the use of one engine, which had worked the flying resource before establishing on grain drying agregate. Experience of exploitation of this plant talks that quality of grain is higher, than was during application of regular drying agregates, that were worked on coal dust and diesel.

Experience of construction and exploitation grain drying plant on the base of aviation GTE of tyoe Д-25В showed considerable fuel economy and technical exploitational expediency of application of aviation GTE in form of heat generators in plants for agrarian products drying. In a table.1 there are information about the low temperature ejector plant on the base of aviation GTE.

Ejector gas generator (Т3 =325 К)

Table 1

| Engine type | Ejector parameters | Generator humidity productivity, kg/hour | ||

| Relative air consumption | Gas consumption, kg/hour | Relative surface | ||

| ТВ2-117А | ||||

| АИ-25 | 3,3 | |||

| АИ-24 | ||||

| АИ-20 | ||||

| Д-30 |

As we see, the ejector gas-turbine plants provide the large values of the productivity of humidity. So, for example, plant on the base of engine of ТВ2-117А can provide drying of 3 - 4 t/hour of hay and separation of surface humidity from 80 t of potato. Thus plants with aviation GTE have considerably less mass and sizes (in 50 - 60 times) in comparison to the traditional ejector-ventilation plants (table.2).

Comparing characteristics of heat transfer from different sources

Humidity 1800-2000kg\hour

| Parameters | ТГ-25А | ВПТ-600 | СФО-250 | СТД-3010 | ТВ2-117А |

| Agregate quantity, piece | |||||

| Fuel consumption, kg/hour | - | - | |||

| Electrical energy consumption, кWt\ hour | - | ||||

| Exploitational losses, rub/hour | |||||

| Mass, kg | |||||

| Sizes, mm | 96900×46400 ×40000 | 61200×18000 ×33000 | 56000×36000 ×47000 | 126000×55000 ×50000 | 2000×600 ×300 |

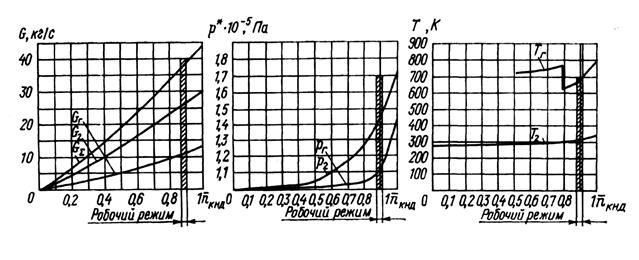

One of perspective directions of application of aviation GTE is a construction of automatic power units of the multi-purpose setting in ground options. The example of such use of aero-engines is power unit which is executed on the base of АИ-25. This power unit consists of engine of АИ-25, which is set on a fundamental frame, fuel system, systems of electric start, automatic control, defence and control.Power unit from АИ-25 can be used in ground conditions for receiving: the compressed air and hot gas in the ships energosystems on air pillows; heat transfer of drying plants and other. On pic. 5 there are parameters of air and hot gas from the І and ІІ contour outlet of engine АИ-25 depending on frequency of rotation of turbo-compressor.

Pic.5. Characteristics of АИ-25 power unit

Using given data, it is possible to execute the project of estimation of basic parameters of the

corresponding ground setting at application of power unit of АИ-25.

Дата добавления: 2015-08-27; просмотров: 73 | Нарушение авторских прав

| <== предыдущая страница | | | следующая страница ==> |

| Kyiv 2008 | | | TASK VARIANTS AND SEQUENCE OF TASK |