|

Читайте также: |

GreenBLAZE завоевал интерес Chemical Engineering

13.04.2015

ADGEX Limited с гордостью сообщает, что в апрельском номере журнала Chemical Engineering была опубликована статья о greenBLAZE - прорывной технологии производства топлива из любых органических материалов!

Chemical Engineering – это ежемесячно издаваемый журнал с международной аудиторией, публикующий новости, технические исследования, обзоры, инновационные решения, и современные тенденции в различных областях химической индустрии.

ТОП-менеджеры и ведущие инженеры нефтехимической, газовой, металлургической промышленности, производственных, перерабатывающих, а также многих других Компаний ежедневно обращаются к Chemical Engineering для поиска и последующего внедрения эффективных, современных и прибыльных решений в свой бизнес.

Управляющий Директор ADGEX Limited, Виктор Узлов, отметил, что публикация в Chemical Engineering – это не просто освещение нашей технологии в иностранной прессе. Chemical Engineering – это одно из самых доверяемых изданий на рынке химической индустрии. Насчитывая более 60,000 подписчиков в более, чем 165 странах, и более 1.7 миллионов ежемесячных просмотров онлайн версии журнала, интерес Chemical Engineering к нашей технологии означает стопроцентное привлечение глубокого внимания и интереса читателей к нашей технологии.

Ознакомиться со статьей Вы можете по ссылке ниже:

http://www.chemengonline.com/making-fuels-almost-organic-material/

Making fuels from almost any organic material

By Paul Grad | April 1, 2015

Share on facebookShare on twitterShare on emailShare on pinterest_shareMore Sharing Services13

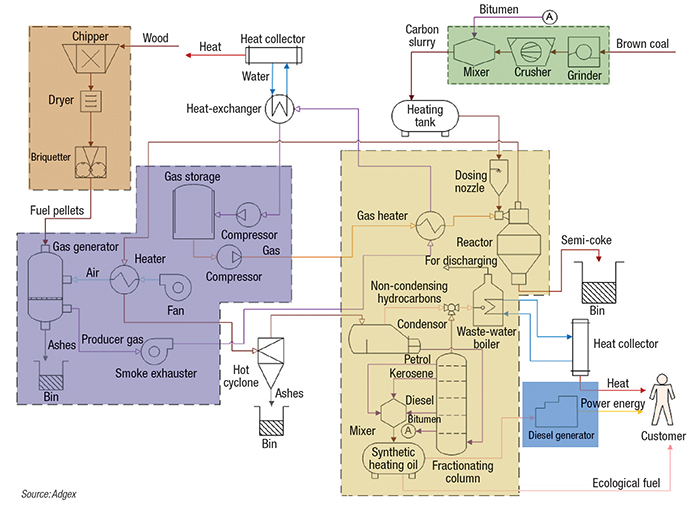

Adgex Ltd. (Sydney, Australia; www.adgex.com) is marketing a plant, tradenamed “Green Blaze,” for processing organic raw materials by means of high-speed ablative pyrolysis. According to the company, the plant (flowsheet) can be adapted to convert into synthetic fuel almost any organic material, including coal, oil wastes, municipal solid waste, industrial and commercial waste, woodchip and sawdust, animal manure and fat, food residues, sewage sludge and other carbon-containing materials. The process of high-speed ablative pyrolysis has the advantage that it allows shifting the balance toward either gaseous or liquid products by adjusting the pyrolysis temperature. The company claims its process produces far greater amounts of heat and fuel, and is far cleaner than other designs.

The process’ efficiency and clean operation are achieved by careful preparation of the feedstock, by using a very small reaction area subjected to a very high rate of heat ingress and with continuous and rapid withdrawal of pyrogases from the reaction area. According to the company, combustion heat of gaseous pyrolysis products can reach up to 12.9 MJ/m3 by virtue of the high hydrocarbon content. Output of gaseous raw material can reach 70 wt.% of dry raw material mass. Solid residue, as hydrocarbon-containing material (semi-coke) can be used as solid fuel. Calorific value of the char can reach 30 MJ/kg.

The company has tested the plant with brown coal. In this case, coal is first ground into particles of 0.5 to 1 mm size. The ground coal is then mixed with liquid pyrolysis products and exposed to additional grinding and homogenization, which generates a carbon slurry from dust-sized particles of coal with size of up to 50µm. The generated carbon slurry is cooled and formed into 25-mm-dia. rods with a length of up to 1 m, which can be introduced into the reactor by a special ingress device. The test reactor worked for about 120 hours in the nominal temperature range of 600–650°C.

Related Content Biomass pretreatment approach can reduce enzyme requirements

Biomass is a recalcitrant, heterogeneous matrix of cellulose, hemicellulose and lignin that resists microbial and enzymatic breakdown. Overcoming this recalcitrance… A catalyst for making aromatic hydrocarbons from biomass

A new catalyst that performs the direct and selective hydrogenolysis of the C–OH bond of substituted phenols and naphthols —… April Chementator Briefs

Nanocellulose pilot Sappi Ltd. (Johannesburg; South Africa; www.sappi.com) will build a pilot-scale plant for low-cost nanocellulose (Cellulose NanoFibrils; CNF) production… Making bio-based PET monomer from furfural

The research group of Yuya Tachibana at Gunma University (Gunma, Japan; greenpolymer.chem-bio.st.gunma-u.ac.jp) has developed a procedure for the production of… Modified MOFs could cut carbon-capture costs in half

Chemists from the University of California, Berkeley (UC Berkeley; www.berkeley.edu) have modified a metal-organic framework (MOF) compound with diamines, which…

Дата добавления: 2015-09-04; просмотров: 35 | Нарушение авторских прав

| <== предыдущая страница | | | следующая страница ==> |

| ПОДСТРЕКАТЕЛИ | | | Первоочередные действия экипажа судна при посадке на мель. |