Читайте также:

|

| Drilling line is usually made of wire rope that generally ranges from 11/8 to 11/2 inches in diameter. Wire rope is similar to common fiber rope, but wire rope is made of steel wires and is a fairly complex device. As wire-rope manufacturers like to emphasize, a wire rope is in itself a machine in the sense that it requires lubrication. This is because the constant movement of strands within the wire rope rub against one another as the rope flexes over sheaves in the blocks. Because wire rope is an expendable item, it can be an appreciable |  Fig. 3. Fig. 3.

|

expense on any drilling rig; this is particularly true unless a planned program of purchase and use of the wire rope is in effect from the beginning.

Although the wire rope looks very much like cable, it is specially designed for the heavy loads encountered on the rig. To achieve the greatest economy from the use of wire rope on a drilling rig, the line selected should be in accord with both the load requirements and the design of the sheaves in the travelling block and crown block through which the line must travel. The line should be frequently inspected to ensure that it is in good condition. The drilling line should be moved periodically (slipped is the field term) so that it wears evenly as it is used. Cutoff procedures should take into account the amount of usage or work done by the wire rope. Wire-rope wear is determined by the weight, distance, and movement of wire-rope travel over a given point.

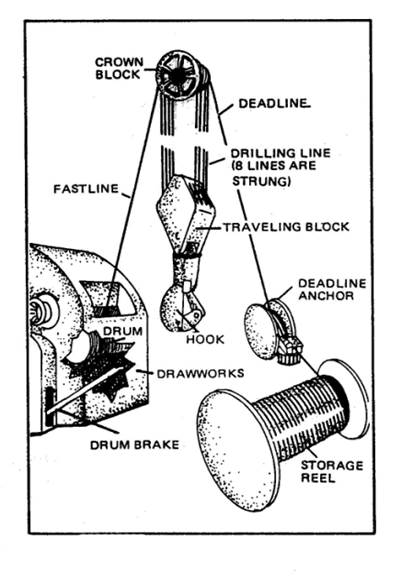

For wire rope to be useful as the drilling line, it has to be strung up, for it arrives at the rig wrapped on a large supply reel. The first step in stringing up the drilling line is to take the end of the line off the supply reel and raise it to the very top of the mast or derrick, where a large, multiple pulley is installed. This large set of pulleys is called the crown block. The pulleys are called sheaves (pronounced "shivs").The drilling line is reeved (threaded) over a crown-block sheave and lowered down to the rig floor. On the rig floor rests(temporarily) another very large set of pulleys or sheaves called the traveling block.

The end of the line is reeved through one of the traveling-block sheaves and is raised again up to the crown block. There the line is reeved over a sheave in the crown block, lowered back down, and reeved through the traveling block.

. This is done a number of times until the correct number of lines has been strung up. Stringing up is usually done with the mast lowered.

The number of lines, of course, is only one; but, since the drilling line is reeved through the crown block and traveling block several times, it gives the effect of many lines. The number of lines strung depends on the weight to be supported. The more weight to be supported, the more lines are needed and vice versa

2. Answer the following questions:

1. What is the drilling line made of?

2. What is the usual diameter of the drilling line?

3. Does wire rope require lubrication?

4. Why does it need lubrication?

5. Why is wire rope an appreciable expense on any drilling rig?

6. What should be done to achieve the greatest economy of the use of wire rope on a drilling rig?

7. How is the wear and tear of the wire rope determined?

8. What should be done with wire rope to use as the drilling line?

9. What should be taken into the account during the cutoff procedures?

10. What is the first step in stringing up the drilling line?

11. How is the correct number of lines strung up?

12. What is a large set of pulleys called?

13. What is called the crown block?

14. What is called the travelling block?

15. What does the number of lines strung depend on?

Дата добавления: 2015-10-24; просмотров: 152 | Нарушение авторских прав

| <== предыдущая страница | | | следующая страница ==> |

| Mach the following words and expressions with their definitions and give their Russian equivalents. | | | Read and translate the text. |